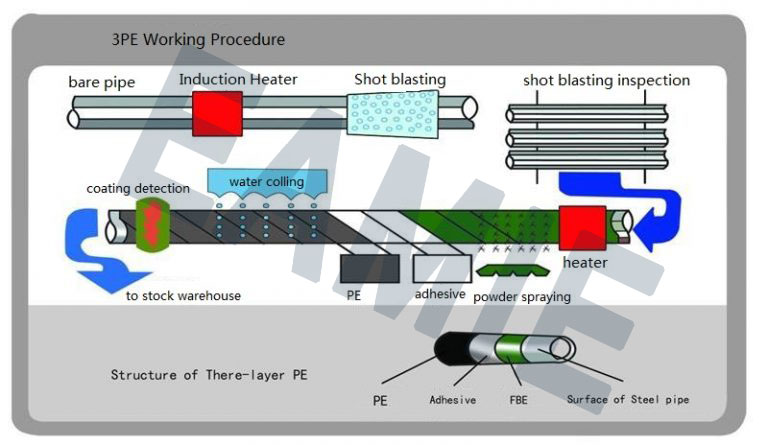

Three Layer Pipe Anticorrosion Processing Line

Working Procedure

Steel pipe will be induction heated, then transferred to shot blasting procedure. After dust removing check, steel pipe will be transported to pipe rack, where it will be put into epoxy powder coating line automatically.

Steel pipe will be heated again to enhance the adhesive force for epoxy powder. Powder coating, adhesive layer coating, PE layer coating will be finished gradually with a T shape equipment placement.

After PE layer coating, the whole pipe will be cooled by water, and sent into anticorrosion layer check (powder, adhesive layer, PE layer).

Finished pipe will be stocked in the warehouse for further usage. End beveling can also be done after this.

Machine List:

- pipe transportation system

- shot blasting machine with necessary line

- induction heater and controlling cabinet

- powder spraying system

- PE layer extruder and parts

- Adhesive layer extruder and parts

- Machine head for extruders

- Air compressor whole set, including air tank, air filter and air dryer

- Material feeder

- Water cooling system, including splash screen

- Pipe beveling machine and parts

- Whole line controlling unit